I regularly conduct kitchen audits in clubs to identify problem areas and make recommendations for improvements. As such, I see patterns emerging across multiple sites, one of which is the lack of effective verification activities for food safety.

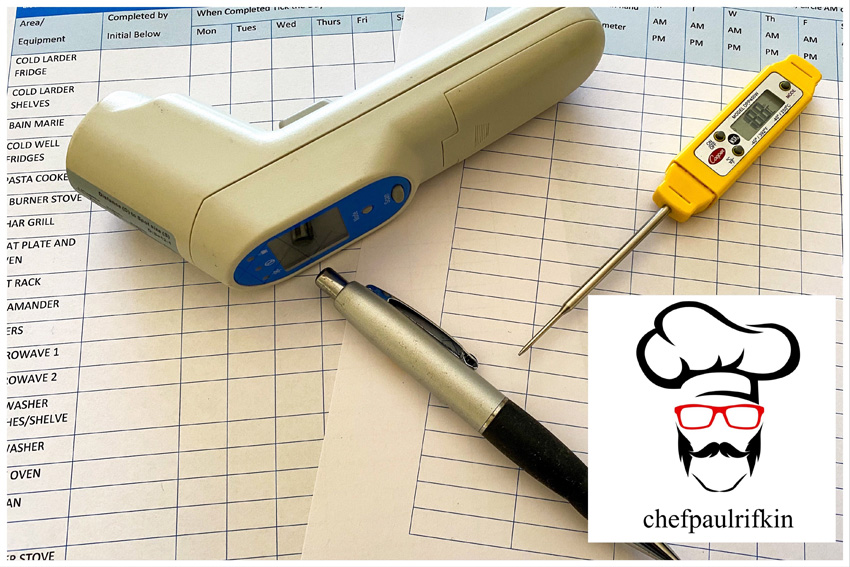

“But my site has recording sheets,” I hear you say. Many kitchens do have such systems in place and a number are completed correctly. Unfortunately, the majority are left incomplete or filled out inconsistently.

For example, fridge temperatures recorded only four out of seven days, occasional cooling temperature checks, few delivery receival temperatures, cleaning sheets with days left unchecked, maintenance schedules left incomplete and calibration checks that are not feasible as no one has a thermometer.

Without some form of verification activity from a manager, the kitchen staff often forget such duties. With a manager checking that the activity was recorded correctly, they can then reinforce the need to comply.

For a chef today, these responsibilities add to the growing job list, and are often seen as items “I’ll do when I have time”.

At the same time, EHO’s require more compliance and documentation. This is critical to ensure safe food practises are being performed.

Why? Put simply, they have to ensure that customers are receiving safe food and, if there is a food-borne illness, it needs to be traced back to its source.

To trace the path of a product, it must be recorded at delivery, during storage and throughout production and cooking. While this is onerous, it’s a requirement of a food licence.

How does technology help?

With digital and live recording, the recorded temperatures are exact and can’t be altered.

Technology that is currently available in the market:

Data loggers for all cool rooms and fridges

These provide live temperature recordings and temperatures outside the safe zones trigger alarms that escalate from notifying the chef, to alerting the fridge mechanic.

Temperature recording of activities

Delivery temperatures are recorded with a manual temperature input or a probe to system input. Some systems have manual invoice entry, while the best one have invoices that are photo recorded.

Cooling temperatures

Manual or probe and graph recording that results in exact information.

Activity recording

Cleaning, calibration, maintenance, food borne illness, wastage.

Staff

Training records and sickies taken.

All digital systems provide a digital record that the activity really took place and can easily be verified by a manager and EHO from both on- and off-site.

Which system is for you?

It depends on the size of the operation and the level of verification required.

Prices can vary from $15 to $150 per month for leased fridge sensors, while others need to be purchased up front. Battery life varies from one to three years for fridge sensors.

Most temperature sensor suppliers have food safety system recording software available in a package that has monthly fees. The complexity or simplicity of systems ranges from app-based to simpler ones.

Consider what suits your venue and staff the best, for both price and features.

Key things to look for:

- Data logger info is live and can be calibrated

- Required activities are recorded

- Results can be verified off-site

- Staff have easy access

- Duties not completed are highlighted

Now is the time to adopt technology into your club as the time saving and compliance advantages outweigh the costs.

Paul Rifkin / chefpaulrifkin consulting / club mentoring and fine tuning specialist / chefpaulrifkin@hotmail.com